-

Rodamientos de cerámica

-

608 transportes de cerámica

-

Transportes de cerámica híbridos

-

Transporte del carburo de silicio

-

Transporte de desplazamiento de cerámica

-

Rodamientos de rodillos de cerámica

-

Cojinete empuje de cerámica

-

Cerámica estructural avanzada

-

Bola del nitruro de silicio

-

Bola del carburo de silicio

-

Bola de cerámica de la circona

-

Rodamientos del carburo de silicio

-

Rodamiento de bolitas del nitruro de silicio

-

Transporte de cerámica de la circona

-

Lacre mecánico

-

RobertaSus transportes de cerámica están de alta precisión, buenos calidad y barato. Tenemos cooperación durante muchos años.

RobertaSus transportes de cerámica están de alta precisión, buenos calidad y barato. Tenemos cooperación durante muchos años. -

Olga WeinbergEsta compañía es nuestro confiable y el proveedor profesional de transportes de cerámica durante muchos años, sus transportes de cerámica, que se utilizan en nuestra bomba es bueno en calidad.

Olga WeinbergEsta compañía es nuestro confiable y el proveedor profesional de transportes de cerámica durante muchos años, sus transportes de cerámica, que se utilizan en nuestra bomba es bueno en calidad.

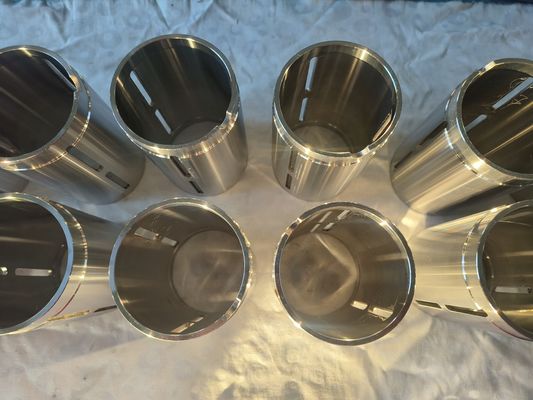

Envases de rodamiento de acero inoxidable personalizados para bomba

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | CSQ |

| Certificación | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Número de modelo | Personalizado |

| Cantidad de orden mínima | 20-50 PCS |

| Precio | negotiable |

| Detalles de empaquetado | Forma+Cartom Box |

| Tiempo de entrega | 20-45 días de trabajo |

| Condiciones de pago | T/t, t/t |

| Capacidad de la fuente | 2000 PC por mes |

| Nombre | Manga de expansión de acero inoxidable | Categoría | Cerámica estructural avanzada |

|---|---|---|---|

| Material | Acero inoxidable | Precisión | Personalizado, según los dibujos |

| Tamaño | Personalizado | Mechón | Forma+Cartom Box |

| Resaltar | Buje de rodamiento de acero inoxidable para maquinaria de alimentos y bebidas,Rodamiento liso para equipos farmacéuticos y médicos,Manguito de expansión para equipos químicos y petroquímicos |

||

Un busto de manga de acero inoxidable, también conocido como busto de rodamiento de acero inoxidable o rodamiento plano, es un componente mecánico cilíndrico hecho de acero inoxidable.Su función principal es apoyar los ejes giratorios o recíprocos, que sirve como una parte de desgaste sacrificial que protege el eje más caro y la carcasa del equipo.

Su principal ventaja sobre las bujes de acero estándar es su excepcional resistencia a la corrosión, lo que lo hace adecuado para ambientes húmedos, químicos y aplicaciones con altos requisitos de higiene.

El rendimiento de la caja está determinado principalmente por su grado de acero inoxidable.

- Acero inoxidable 304:Un acero inoxidable austenítico versátil con buena resistencia a la corrosión (especialmente en ambientes atmosféricos y químicos suaves), formabilidad y dureza.industria química general, equipos al aire libre y otros entornos no severamente corrosivos.

- Acero inoxidable 316:Contiene molibdeno (Mo), que mejora significativamente la resistencia a los cloruros (por ejemplo, agua de mar, salmuera) y a una gama más amplia de productos químicos en comparación con el 304.productos farmacéuticos, procesamiento químico y equipos de blanqueo donde la resistencia a la corrosión es crítica.

- Resistencia a la corrosión excelente:Resiste la humedad, varios productos químicos y no se oxida.

- Alta resistencia y dureza:Capaz de soportar ciertas cargas y impactos.

- Higiénico y no tóxico:Fácil de limpiar, cumple con las normas de la industria alimentaria y farmacéutica.

- Resistencia a la temperatura:Mantiene un rendimiento estable en un amplio rango de temperaturas.

Las carcasas de manga de acero inoxidable se utilizan ampliamente en varias industrias que requieren prevención de óxido y resistencia a la corrosión:

- Maquinaria de alimentos y bebidas: rellenos, mezcladores, transportadores, etc., donde se debe evitar la contaminación y es esencial una fácil limpieza / saneamiento.

- Equipos farmacéuticos y médicos: Extremadamente altos estándares de higiene, que necesitan soportar varios agentes de limpieza y procesos de esterilización.

- Equipo químico y petroquímico: lugares de rodamiento en bombas, válvulas y agitadores, resistentes a la corrosión de los medios químicos.

- Ingeniería marina y marina: maquinaria de cubierta, componentes de hélices en buques, resistentes al agua de mar y a los saleros.

- Equipo de tratamiento de agua y protección ambiental: tratamiento de aguas residuales, bombas de agua y otros entornos húmedos/químicos.

- Máquinas textiles y de papel: que funcionan en ambientes de alta humedad, alta temperatura o que contienen lejía.

Nuestro logotipo de empresa es ZXSQ y CSQ, y posee once patentes de invención para modelos de utilidad.para ofrecerle un servicio de alta calidad y perfecto, de acuerdo con los requisitos del cliente para ordenar una variedad de productos de rodamientos.

Desde el año 1982 hemos acumulado una experiencia abundante en la producción en los últimos más de 40 años,dedicándonos de todo corazón a la investigación y el desarrollo de material de rodamiento cerámico, nuestra técnica de procesamiento y la mejora de nuestros equipos.

Habiendo experimentado varias evoluciones y transformaciones, nuestra empresa se ha convertido ahora en la empresa líder en el mercado interno de China en los campos de rodamientos cerámicos y productos de materiales cerámicos.

En la actualidad, tenemos una línea de producción de molienda y montaje totalmente automática para rodamientos cerámicos, con una producción anual de 3 millones de juegos de 608-2PS,608-2RS y otras especificaciones de los niveles de precisión P5 y P4.

Nuestra empresa cuenta con los equipos más avanzados en el campo de la producción de cerámica industrial nacional,además del horno de sinterizado isostático en caliente (HIP) importado de ABB SueciaNuestra empresa también cuenta con otros equipos de producción, la temperatura de cocción del producto se ha elevado a más de 2000 ° C.

R: Somos una fábrica en Beijing, China. Hemos estado produciendo y vendiendo rodamientos de cerámica durante más de 40 años.Hemos establecido relaciones de cooperación amistosas con muchas empresas nacionales y extranjeras.

R: Siempre producimos muestras antes de la producción en masa, y producimos estrictamente de acuerdo con los requisitos del cliente y las regulaciones de producción.utilizaremos equipos de inspección para realizar una inspección precisa de los productos, y nuestro embalaje adopta el doble seguro de espuma y cartón, para garantizar estrictamente la calidad de los productos.

R: rodamientos de bolas de ranura profunda de cerámica, rodamientos de bolas de contacto angular de cerámica, rodamientos de bolas de cerámica híbridos, rodamientos de cerámica lineales, etc. y todo tipo de bolas de cerámica.

R: Somos una empresa integrada en la industria y el comercio, tenemos tres fábricas, con el equipo de producción e inspección de hoy, podemos proporcionar mejores fechas de entrega y calidad del producto.

R: Proporcionaremos productos de alta calidad y servicios personalizados, que pueden ser completamente personalizados de acuerdo con las necesidades del usuario. Podemos proporcionar muestras para la confirmación del cliente.

Suministramos rodamientos, productos de alta calidad, si necesita comprar o consultar el precio de los rodamientos, póngase en contacto con nosotros.servicio en una de las empresas profesionales de rodamientosSeleccionamos materias primas de alta calidad, hacemos cuidadosamente cada juego de rodamientos.

Nos adherimos a la demanda del cliente como guía, y nos esforzamos por proporcionar a los clientes productos de calidad y servicio postventa, crear valor para los clientes, hacer socios de los clientes.Bienvenido a discutir la cooperación!

Calificación General

Imagen de calificación

La siguiente es la distribución de todas las calificacionesTodas las reseñas